As certified energy auditor kleinkraft assesses energy efficiency measures of its customers for the acknoledgement according to the...

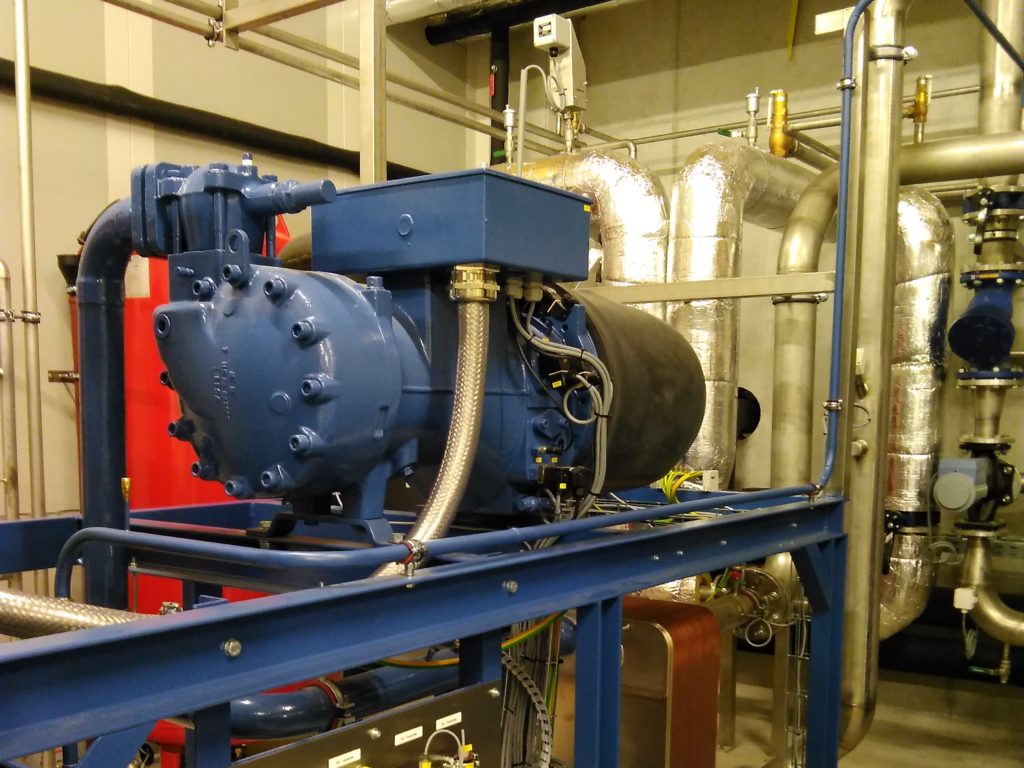

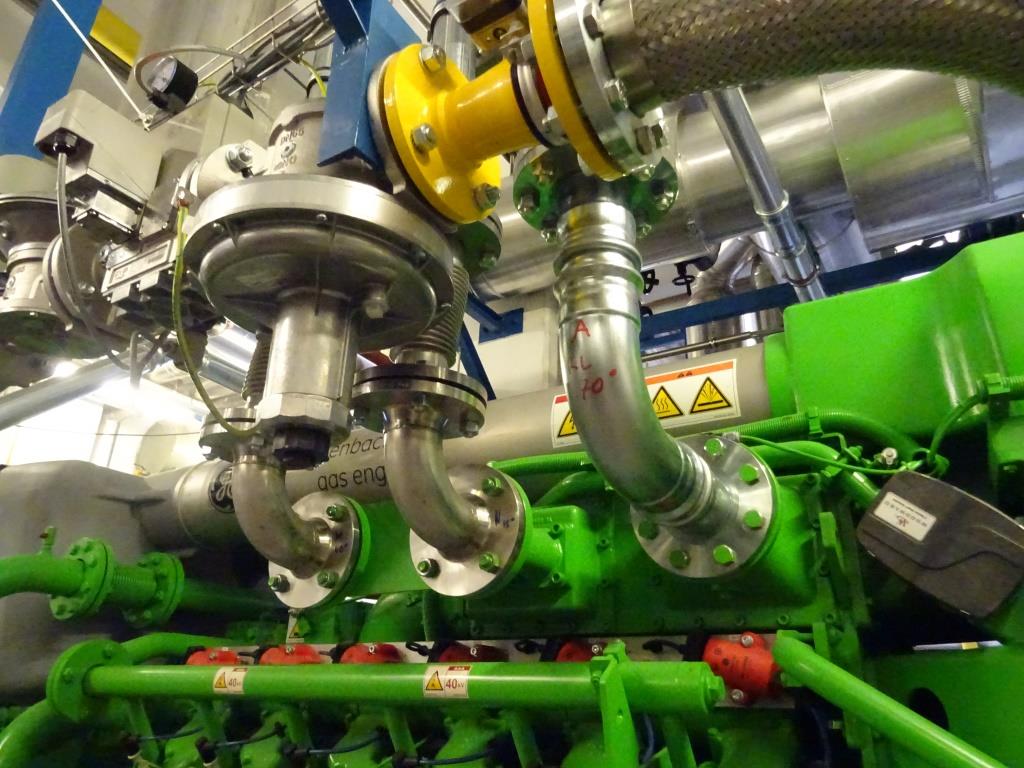

Energy efficiency measures

Energy efficiency measures

As certified energy auditor kleinkraft assesses energy efficiency measures of its customers for the acknoledgement according to the Austrian energy efficiency law. Energy efficiency measures result in energy savings of electricity and natural gas. Within the assessed projects of big and well-known industrial companies yearly energy savings are achieved:

- 7.154.381 kWh/year